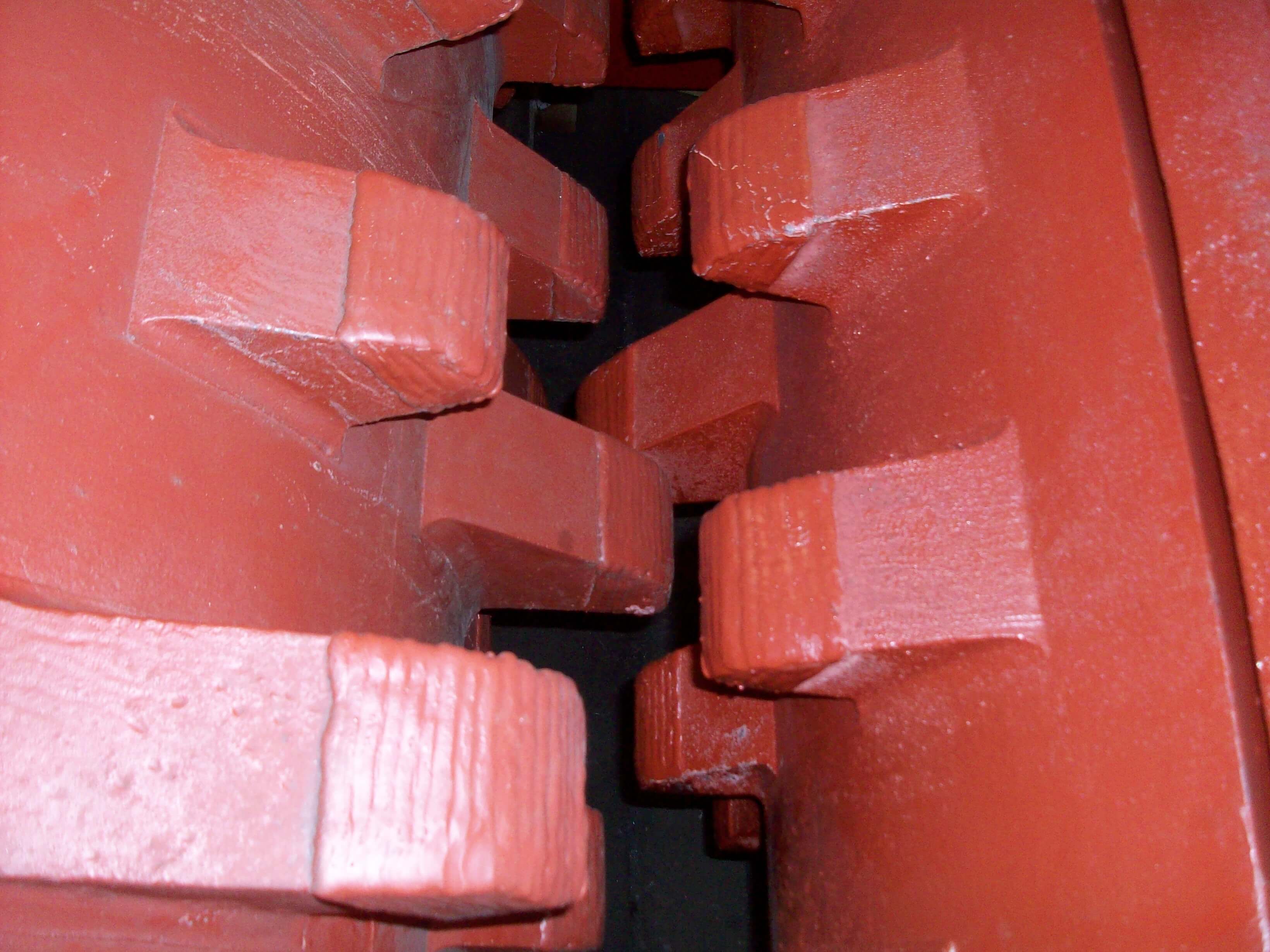

Crushing

Crushing is often one of the first steps in the production of rock, coal and other minerals, as mined material can consist of boulders that are too big to fit through the processing plant. The type of crusher required depends on the material being reduced. McLanahan specializes in a variety of crushing solutions for reducing minerals – from very friable minerals, such as coal and salt, to hard rock, such as granite, and ore-bearing minerals, such as copper and iron – at the primary, secondary and tertiary stages using compression, impact, attrition or shear forces.