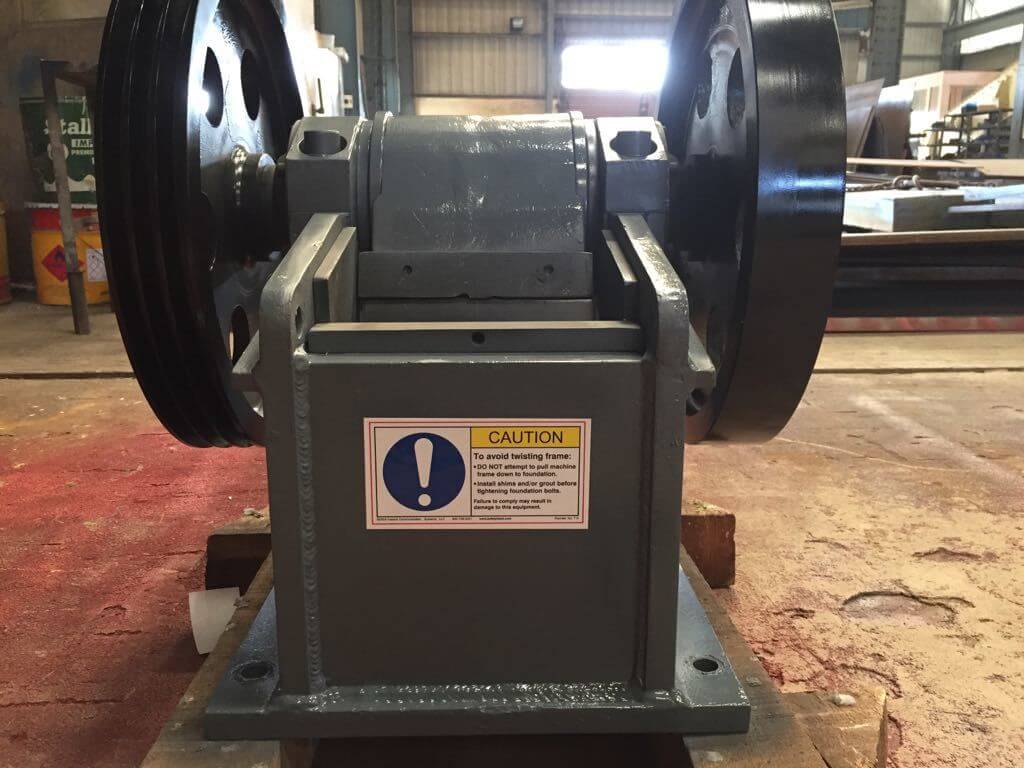

Using a significantly oversized crusher to handle the crushing requirements in either type of scaled-down material handling system is not an effective option for a number of reasons, not the least of which is a lack of cost-effectiveness. Dependable, heavy-duty crushing options for low feed rates is a market niche covered by the McLanahan line of sample crushing products. From Jaw Crushers, to Hammermills, to Double Roll Crushers, an option likely exists within the McLanahan product offering that will meet your low tonnage, high dependability requirements.

Sampling and pilot crushers are used with the same types of materials as their larger counterparts. The key difference is comparatively low feed rates.

Some common uses include mechanical sampling systems for various bulk materials, test plants for new process development, pilot plants for small-scale process evaluation and laboratories for batch processing of samples collected by mechanical sampling systems.

Why McLanahan Sampling/Pilot Plant Crushers

McLanahan Corporation has extensive experience making small particle sized material out of large particle sized material. While this may not seem like a terribly difficult endeavor, accomplishing this action correctly with heavy-duty reliability and dependability is no small undertaking. That is why a company like McLanahan is ideal when it comes to applying the knowledge gained in difficult, high flow rate processing applications to the equipment needs of application in low flow rate processing applications for the same bulk materials. We combine this with our expertise in mechanical sampling systems and the producers’ laboratory and testing needs to provide the right sample crusher for your material.