Introduction

Coal is categorized into four rankings based on carbon content: anthracite coal (hard coal), which has the highest carbon content; bituminous (soft coal); sub-bituminous; and lignite (brown coal), which has the lowest carbon content.

Each type of coal has differing degrees of friability, meaning how hard it is, how brittle it is and how it breaks up. This is measured by the Hardgrove Grindability Index (HGI).

After coal is extracted from the earth, it can be delivered as raw coal to wash plants or reduced to the proper particle size at the mine and transported for its intended use.

The two main uses of coal are for power generation and steel production. In order to yield the highest thermal and financial benefits when shipping direct, the coal is often crushed to 2” x 0 to maximize the haulage capacity of trucks and trains. It is then transported to power plants and steel plants with minimal loss of volume.

Ideally, the seller and buyer want the coal to contain as little waste, or fines (-30 mesh), as possible to optimize the value of the product.

During the crushing phase, there several are steps that can be taken to minimize fines generation and increase the product yield.

Lower roll speeds

Whenever coal is handled, whether by man or machine, it tends to degrade. The minute particles that form coal dust are the results of coal degradation. Therefore, it stands to reason that the more gently coal is handled, the less it will degrade.

Even though you are intentionally degrading the material as part of a necessary process when crushing coal, you can expect fewer fines to be generated with slower action or rotational speeds of the crushing device.

Many crushers have the built-in ability to run faster than their optimal speeds to produce at higher rates. If the throughput capacity is more important to you than controlling fines, then higher speeds may be the choice.

Multiple crushing stages of lower reduction ratios

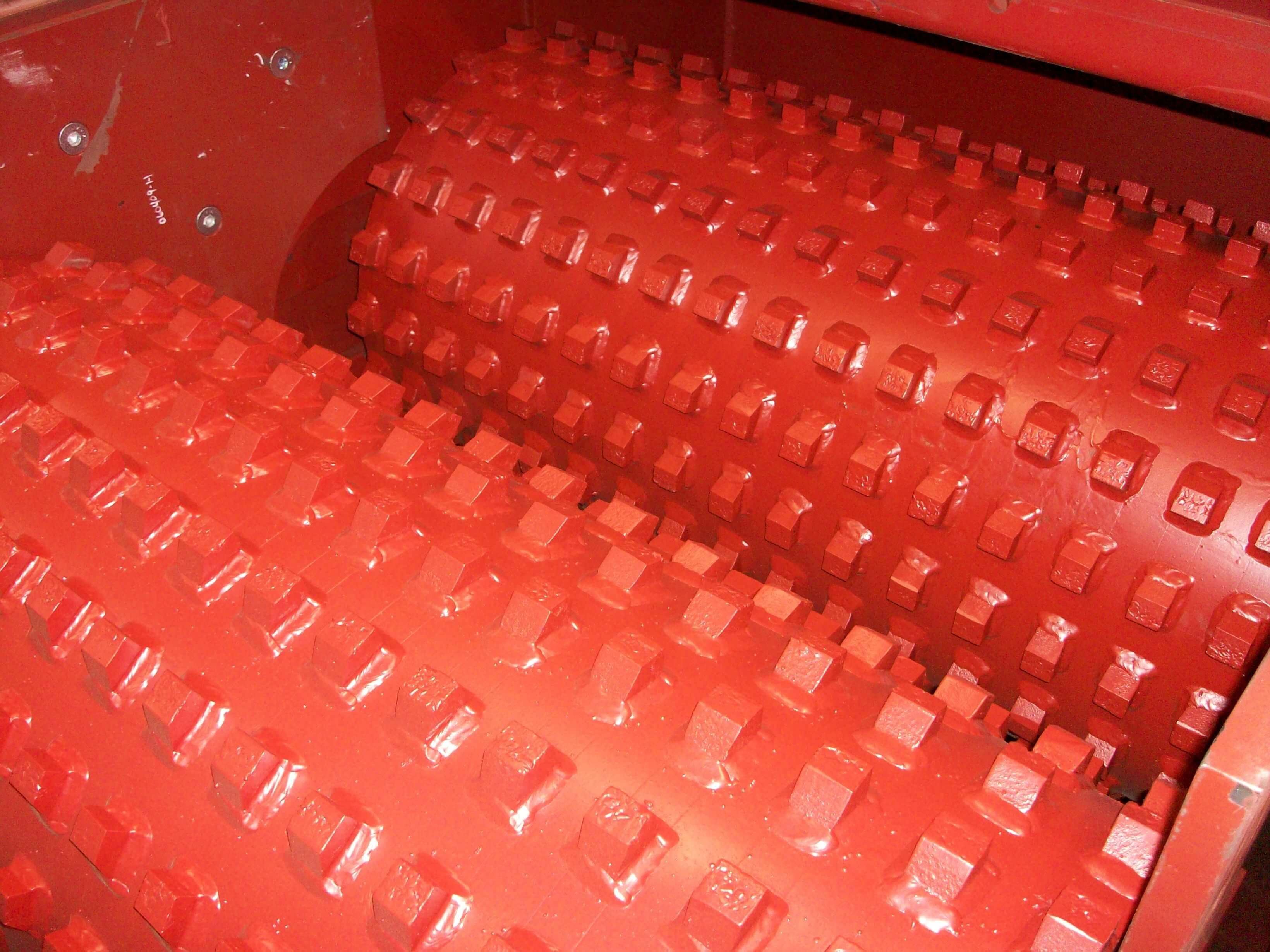

When reduction ratios of the coal can be decreased to 4:1, 3:1 or 2:1 (in Roll Crushers, for instance), the feed material can more easily pass through the crushing zone with unimpeded, continuous flow. This means the material is only briefly in contact with the crushing elements and does not encounter the crushing teeth for more than a single rotation.

If the reduction ratio exceeds 4:1, there is a higher incident of tooth contact with larger lumps taking longer to pull through. This results in grinding of the coal and the generation of a higher percentage of fines.

Crushing coal to reduced ratios may require an additional stage of crushing to achieve the final product. Although adding a third crushing stage may add to capital expense at the onset, the higher yield and reduced wear and tear on the crushers over a sustained period of time may pay dividends down the road.

Screening between crushing stages

As stated previously, the less the coal is handled and the more gently it is handled, the likelihood of lower fines generation. A popular thought pertaining to this premise is, “Why subject coal that is already to size to further crushing?” By using Vibratory Screens to separate and bypass sized coal from further crushing, you are not subjecting the material to further degradation.

Properly sized screens can be specified to make the desired separations after any crushing stage. Using screens may also decrease the capacity required of one or more crushers, allowing for smaller, less expensive crushers in one or more stages of the circuit.

All of the above methods of operation have been proven to reduce or minimize fines generation in coal crushing circuits. Considerations for implementing them are:

- the type of coal with regard to friability (HGI)

- the weighted importance of production capacity vs. the percentage of fines in the product

- the capital budget of the plant owner

- long-term expectations and economic benefits

If you need assistance determining the best method for reducing fines at your site, contact us today!